I was looking at the X-Pump Block for a customer that wanted to install this

with a new domestic water heater with side taps for a radiant floor heating system. I understand the concept but the design procedure I didn’t understand fully. Here’s the application, 50,000 btu radiant floor in a concrete slab, 5 loops at 275 ft per loop. I looked at the x block and when I came to the btu capacity that’s when I got confused. I’m looking for a good explanation of how the btu compacity works. – George from NJ

with a new domestic water heater with side taps for a radiant floor heating system. I understand the concept but the design procedure I didn’t understand fully. Here’s the application, 50,000 btu radiant floor in a concrete slab, 5 loops at 275 ft per loop. I looked at the x block and when I came to the btu capacity that’s when I got confused. I’m looking for a good explanation of how the btu compacity works. – George from NJ

George,

When using an X-Pump Block (XPB), since there is a heat exchanger built in, you want to make sure it is the properly sized.

You need to know several numbers first; the water temperature of the radiant floor and the available water temperature of the heat source.

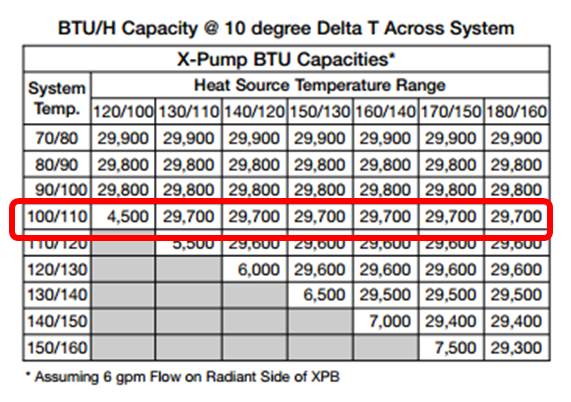

For example if your radiant floor design temp was 110 degrees F with a 10 degree Delta T, we would look at the chart on page 3 of the instructions and then see the amount of BTU’s we could deliver at different heat source temperatures. Based upon the BTU load of your project at 50,000 BTU’s, the XPB cannot work for this application when we use a 10 degree delta T across the radiant floor.

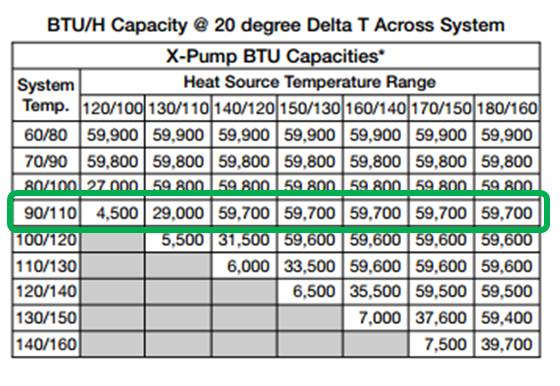

However, if we increase the Delta T across the system, we would use chart 2 on page 3 and looking at the BTU requirements, we can see that it will work. The minimum temperature required from the heat source will be 140 degrees. If you have a higher temperature available, you are still maxed out at the 59,700 BTU’s that you can deliver to the system because of the size of the built in heat exchanger.

But we are not done yet with sizing the XPB, we need to verify that the circulators that are integral will be enough to handle your needs. When we use the universal hydronic formula; GPM=BTUh/(DeltaT x 500) so we can get the flow rate needed.

So let’s put in the numbers we do know;

GPM=50,000/((110-90)x500)

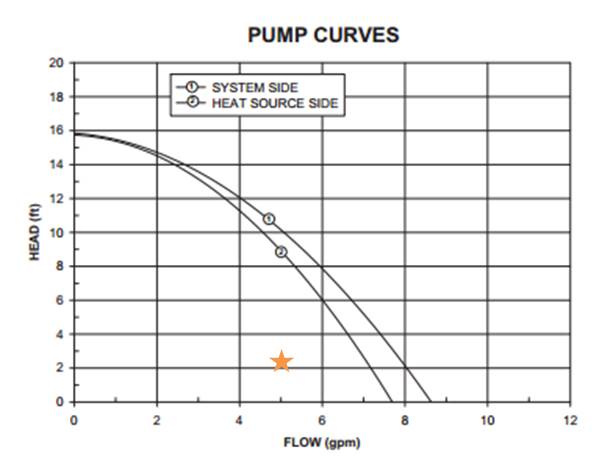

and we get 5 gallons per minute. Based upon the information you gave me, we need to find the head loss and if I were to look at a pressure drop chart for ½” PEX, and the 1 gpm per loop row (five gpm’s total and you have 5 loops…..so 1 gpm per loop). Doing the math and using the chart reveals 1.70 psi pressure drop per 100 feet of pipe. Take a look at the bottom of the chart to convert to foot of head so, (1.7 psi/2.31 FOH) times 2.75 feet equals 2.04 foot of head.

So we now take those numbers, 5 gallons per minute and 2.04 foot of head loss, plot it on the curve and we can see that the circulator built into the X-Pump Block is in fact large enough to handle the radiant project you have.

Now I know I took some liberties here and made some assumptions when doing the math, so if your numbers are different, apply accordingly. I hope this helps when it comes to sizing and selecting the X-Pump Block for your radiant projects.

As always, Enjoy and keep ‘em coming!