Had to pull this out of the archives in my mind and I have had these questions presented to me over the years, just don’t remember where or when or who asked them. Anyway what sparked this was a question was on “The Wall” about sharing the same outdoor sensor on a Taco i-Valve and the boiler in the house. The boiler was already installed and the addition of the i-Valve was designed and selected for a new radiant floor zone in the home.

Can you use the same sensor for both components, i.e. just split the wire in the mechanical room and connect to the boiler and the Taco iSeries Mixing Valve?

Before this gets answered, we need to find out how or what these sensors are. Temperature sensors that we use in hydronic heating systems (outdoor air sensors, water temperature sensors) are thermistors.

The Definition:

Thermistors are thermally sensitive resistors whose prime function is to exhibit a large, predictable and precise change in electrical resistance when subjected to a corresponding change in temperature.

So, as the temperature the thermistor reads raises, there is less electrical resistance in the thermistor; when the temperature gets colder, the resistance goes up. There is a small amout of voltage applied to the sensor wires and the resistance across those wires changes as the temperature changes. We can read this in ohms.

If you were to put two sensors to the same terminals, you would cut in half (be doubling) the electrical resistance therefor affecting the ohm reading and the wrong information would be sent to the controller.

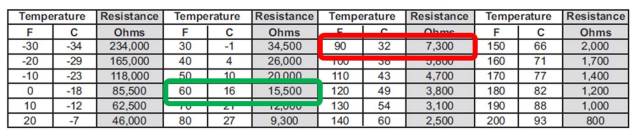

If we look at the following chart (this comes with all controllers that have any temperature sensors),

if there is a sensor outside and the outside air temp is 60F, the controller would internally read a resistance of 15,500 ohms. But since two sensors are tied together, halving (

if there is a sensor outside and the outside air temp is 60F, the controller would internally read a resistance of 15,500 ohms. But since two sensors are tied together, halving (doubling) the resistance, the controller would actually read 7,300 ohms. (30,622 ohms.) Based on the charts, the controller would think it is around 90F outside. (35F outside.) The decisions the controller would make would be wrong and can create havoc when trying to troubleshoot or dial the system in therefor losing efficiency and comfort and all control with that component.

(Author edit: My brain was going faster than my typing and I made some errors when this was initially posted. The strikethroughs were the previous numbers. In order to double the resistance, the sensors would be wired in series. Our example is wired in parallel. Thank to my bud Tim Doran <fellow colleague and Long Islander> for pointing out my error)

A second tech tip I ran into recently in my own home. I had my cousin (a licensed electrician) come to my house to help with the remodel I have going on. As he was working in the electrical

panel, I noticed he was keeping 4-5” pieces of the romex outer jacket in a pile near him.

When I leaned in closer to see what he was doing, he would write on the jacket and slide it over the wire before attaching to the breaker. Yes he does label the main panel cover for each breaker, but I thought this was a great idea for me to use.

That day, I was doing the low voltage wiring for my heating system, running thermostat wires. I have seen plenty of projects where trying to label

the large array of wires coming to a ZVC or SR panel as  daunting and challenging to keep it neat. Using ductape and a marker, the number sticker labels (which still needs a legend), a label printer are options available, but when we are trying to our best work, this sometimes can get sloppy.

daunting and challenging to keep it neat. Using ductape and a marker, the number sticker labels (which still needs a legend), a label printer are options available, but when we are trying to our best work, this sometimes can get sloppy.

Well here is a just another option, and it can never fall off.